PEB vs Conventional Buildings: Which One Should You Choose for Your Next Project?

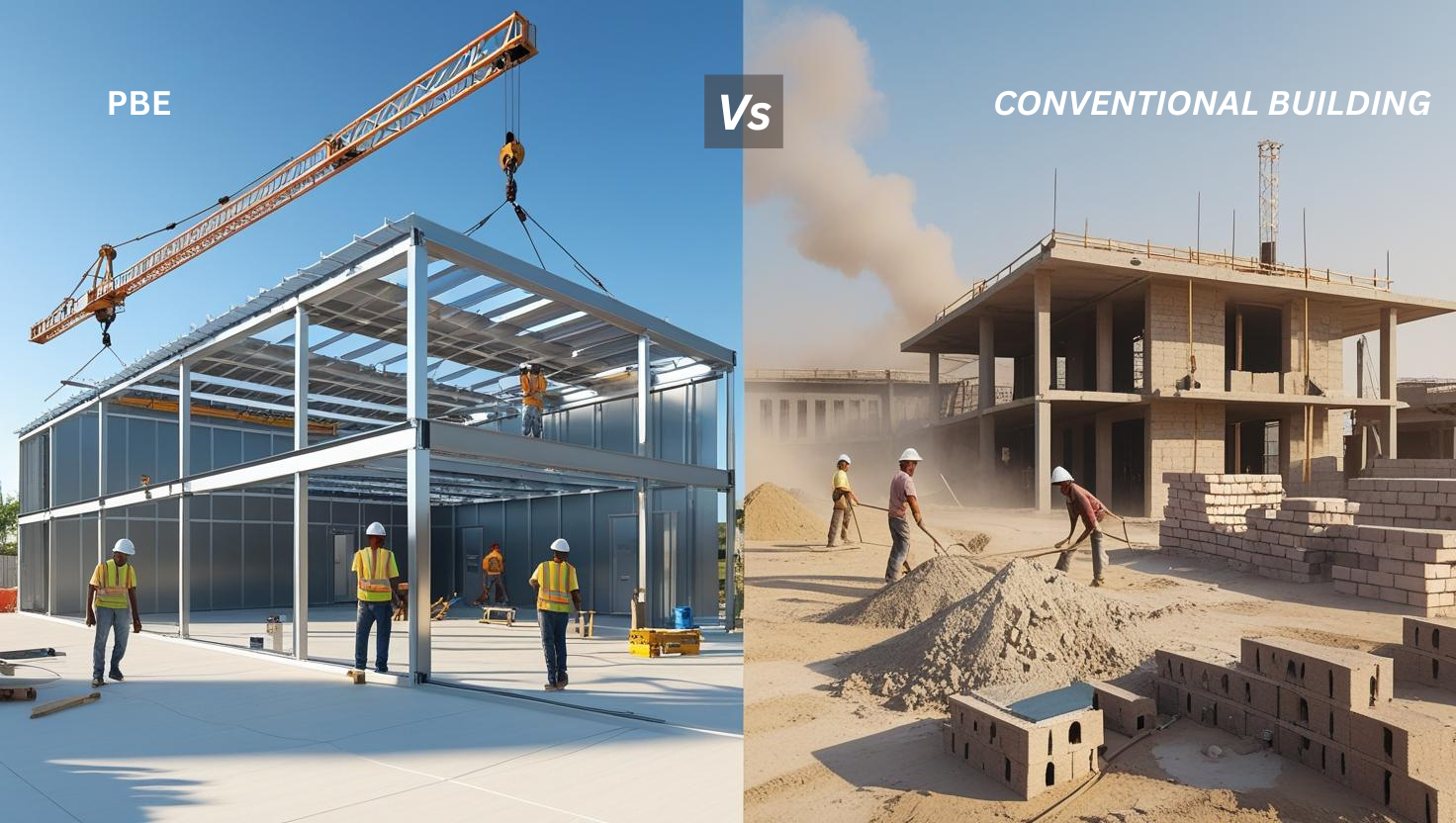

When planning a new industrial or commercial facility, the construction method you choose can greatly impact your budget, timelines, and operational efficiency. Two leading methods are Pre-Engineered Buildings (PEBs) and Conventional Construction.

While both offer unique benefits, they serve different needs depending on the scale, purpose, and urgency of your project. In this blog, we’ll break down the differences between PEB and conventional buildings and help you decide which is best for your next industrial or infrastructure project.

What is a Pre-Engineered Building (PEB)?

A Pre-Engineered Building is a modern steel structure built using components that are designed and manufactured off-site, then assembled at the project location. The design, material specification, and construction process are standardized and optimized for faster completion.

PEBs are widely used in India, Africa, the Middle East, and Southeast Asia across industries such as warehousing, manufacturing, logistics, agro-processing, and energy.

What is a Conventional Building?

A Conventional Building uses materials like concrete, bricks, and reinforcement steel. All construction activities are carried out on-site, including curing, masonry, shuttering, and reinforcement. While it offers design flexibility, it also involves longer timelines and more labor.

Key Differences Between PEB and Conventional Buildings

1. Construction Time

- PEB: Factory-built, with combination of nut & bolt components enable rapid on-site installation.

- Conventional: Time-consuming due to on-site brickwork, concrete curing, and structural labor.

2. Cost Efficiency

- PEB: Lower costs due to reduced labor, waste, and construction time.

- Conventional: High labor costs and material wastage increase the overall expenditure.

3. Design Flexibility

- PEB: Easily adaptable to varying industrial load requirements, supports future expansion, and can be relocated if needed.

- Conventional: Design changes require manual alterations, often causing delays, and the structure cannot be relocated.

4. Durability & Maintenance

- PEB: Built with corrosion-resistant steel and protective coatings, ensuring no seepage issues and minimal maintenance needs.

- Conventional: Susceptible to water seepage and plaster deterioration, leading to frequent repairs and higher maintenance.

Which One is Right for Your Industry?

PEB for Warehousing and Manufacturing:

PEBs are ideal for industries requiring large open spans, such as warehouses, logistics parks, and factories. Rostfrei Steels Pvt. Ltd. offers tailor-made solutions with quick deployment and minimal downtime.

PEB for Agro-Infrastructure:

From cold storage to grain silos, PEBs help agro-industries scale up without worrying about structural limitations. Our modular approach ensures better crop protection and hygiene.

Conventional Structures for Residential or Multi-Story Use:

For commercial offices or housing where aesthetics and zoning regulations matter, conventional buildings offer more architectural freedom, albeit at a slower pace.

Why Choose Rostfrei Steels Pvt Ltd. for Your PEB Project?

Rostfrei Steels Pvt Ltd. is a trusted name in the steel infrastructure industry, known for delivering quality PEBs across India, Africa, the Middle East, and Southeast Asia. With over two decades of experience, we specialize in:

- Tailor-made industrial and agricultural PEBs

- Quick turnaround and deployment

- End-to-end support from design to installation

If you’re looking for a cost-effective, durable, and fast-to-deploy solution, PEBs are the clear choice for modern industries. Their modular nature, scalability, and design precision make them suitable for a variety of sectors—from agriculture to manufacturing.