The Future of Biogas Storage: Glass-Fused-to-Steel Tanks Explained

In the rapidly expanding renewable energy sector, biogas has emerged as a clean, sustainable solution for converting organic waste into valuable resources renewable energy, bio-fertilizers, and cost savings. But generating biogas is only half the challenge; Storing the feed safely and ensuring the proper functioning of anaerobic microorganisms is equally critical.

When it comes to biogas storage, the choice of tank material can make the difference between decades of trouble-free operation and costly downtime. Glass-Fused-to-Steel (GFS) tanks are now taking center stage in the industry, outshining conventional options like concrete tanks or MS painted tanks.

In this blog, we’ll explore what makes GFS tanks the ideal choice for biogas storage, their advantages over traditional alternatives, and why Rostfrei Steels is a trusted name in this technology.

Understanding Glass-Fused-to-Steel Technology

Glass-Fused-to-Steel is an advanced tank manufacturing process where a layer of high-quality glass enamel is fused to the surface of steel at 800–900°C in a kiln (furnace). This high-temperature fusion creates a chemical bond between the steel and the glass coating, producing a finish that is inert, corrosion-resistant, and highly durable.

Key Properties of GFS Tanks:

- Inert & Non-Stick Surface – Prevents sludge from adhering to the tank walls, ensuring easier cleaning and improved hygiene.

- Zero Corrosion – Protects against aggressive chemicals like hydrogen sulfide and ammonia found in biogas applications.

- Non-Reactive – Prevents contamination and ensures consistent gas quality.

- Durable & Long-Lasting – Service life of over 25-35 years with minimal maintenance.

Why GFS is a Game-Changer for Biogas Storage

- Superior Corrosion Resistance

Biogas production involves the breakdown of organic matter, producing gases and liquids that are highly corrosive to traditional tank materials. The glass coating in GFS tanks acts as a permanent barrier, shielding the steel from various gas attack.

Where hand painted epoxy or other coatings may chip or peel over time, GFS maintains its integrity for decades, even in acidic or alkaline environments.

- Maintenance-Free for Decades

With no need for repainting or recoating, GFS tanks drastically reduce operational downtime and maintenance costs. This is a significant advantage for plant operators looking to maximize uptime and profitability.

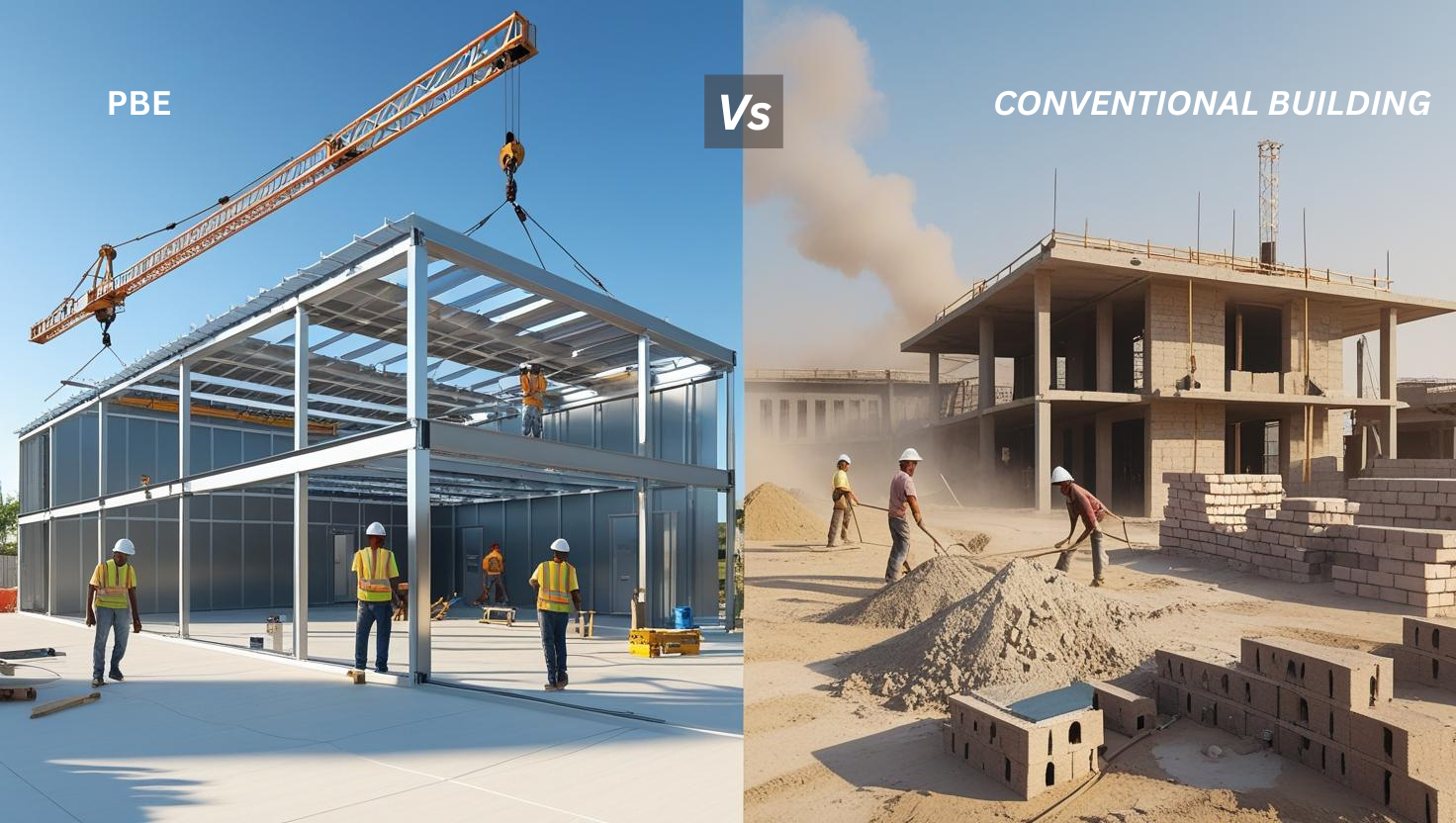

- Modular and Fast Installation

Unlike concrete tanks, which require months of curing and on-site work, GFS tanks are pre-fabricated in modular panels and assembled on-site using a top-to-bottom jack-building method. This means:

- Faster project completion

- Minimal on-site disruption, leaving the work area clean and orderly

- Easy expansion if capacity needs grow

- Global Standards Compliance

Our company is ISO compliant, and our products are certified by several prestigious international bodies, including CE and NSF, ensuring quality, safety, and regulatory compliance.

- Environmentally Friendly

The materials used in GFS tanks are 100% recyclable, and their long service life reduces the environmental impact of replacements or repairs. This aligns perfectly with the green objectives of biogas projects, ensuring lower carbon footprint.

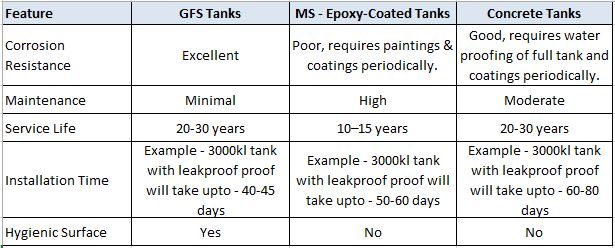

Comparison: GFS vs Traditional Biogas Storage Options

It’s clear that GFS technology outperforms older tank materials in almost every critical category for biogas storage.

Rostfrei Steels – Engineering the Future of Biogas Storage

At Rostfrei Steels Pvt. Ltd., we specialize in delivering world-class GFS tanks for biogas plants of all sizes. With decades of engineering expertise, our tanks are:

- Built from high-grade steel fused with premium glass enamel.

- Designed for quick installation and minimal downtime.

- Certified to global quality and safety standards.

We have successfully delivered biogas storage solutions for agriculture, municipal waste treatment, and industrial applications helping our clients turn waste into a reliable source of clean energy.

Final Thoughts

The renewable energy industry is moving towards technologies that offer long-term reliability, low maintenance, and environmental sustainability. Glass-Fused-to-Steel tanks check all these boxes and more, making them the future of biogas storage.

By choosing GFS tanks from Rostfrei Steels, you’re not just investing in a storage solution — you’re investing in decades of performance, safety, and peace of mind.